Baroda Hitech

Welcome to Baroda Hi-tech

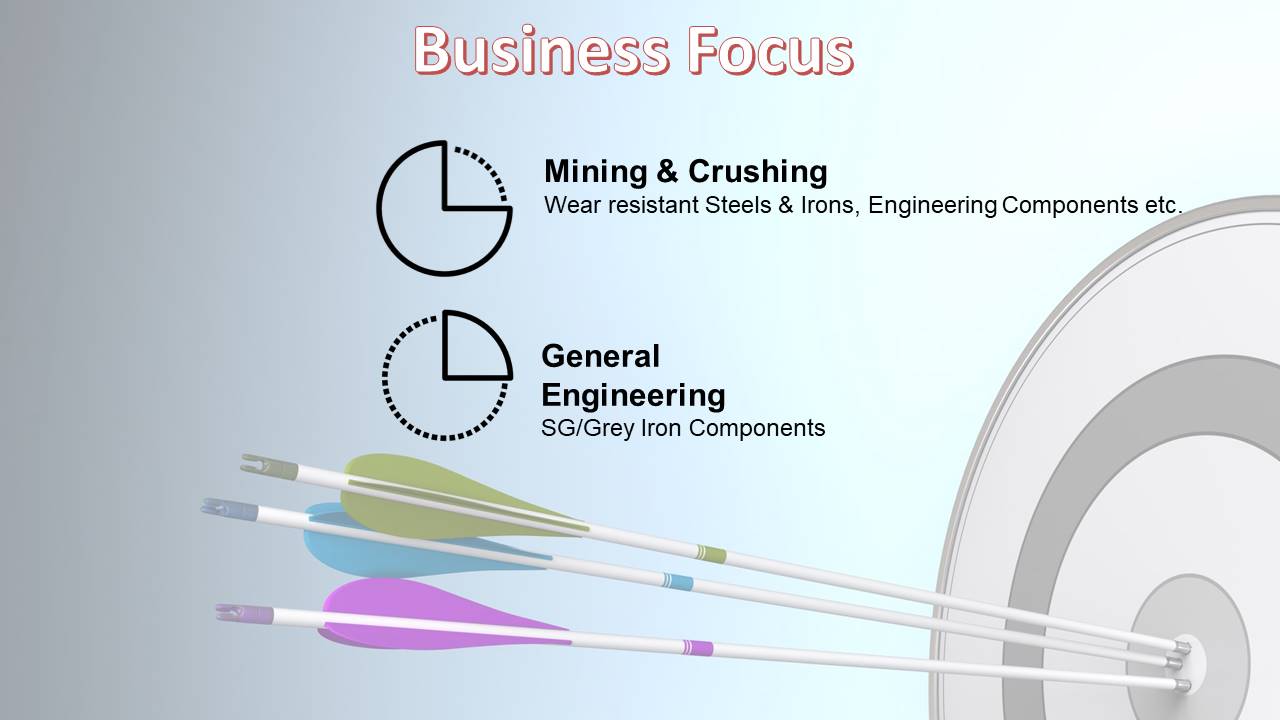

The Company

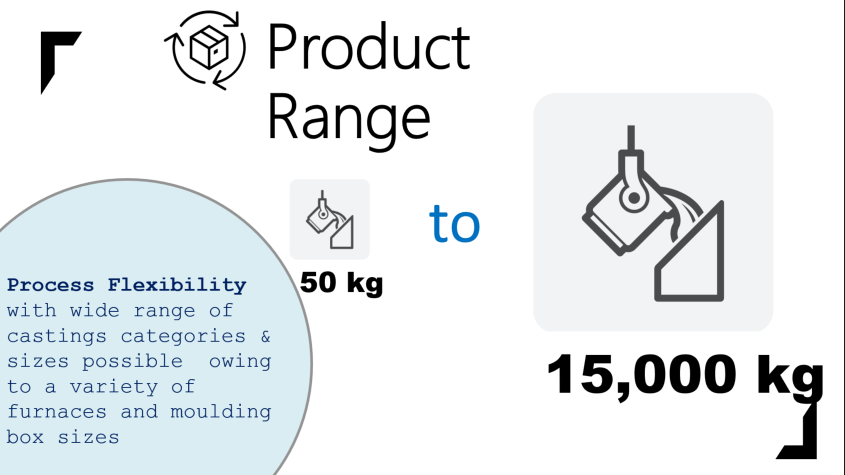

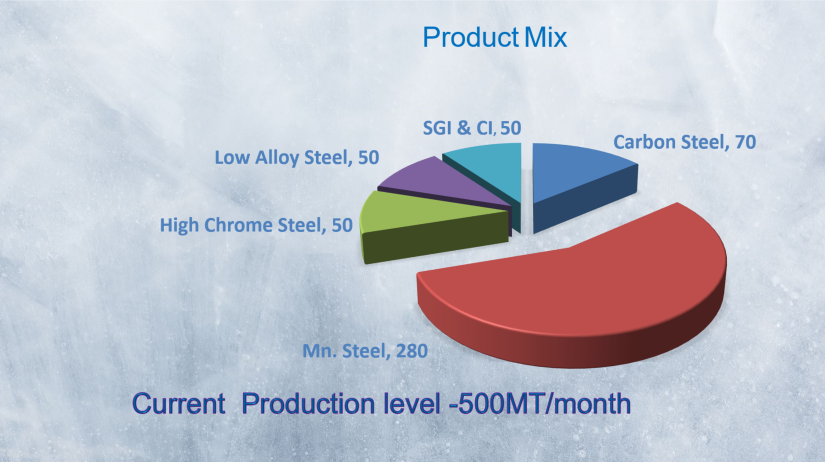

Products

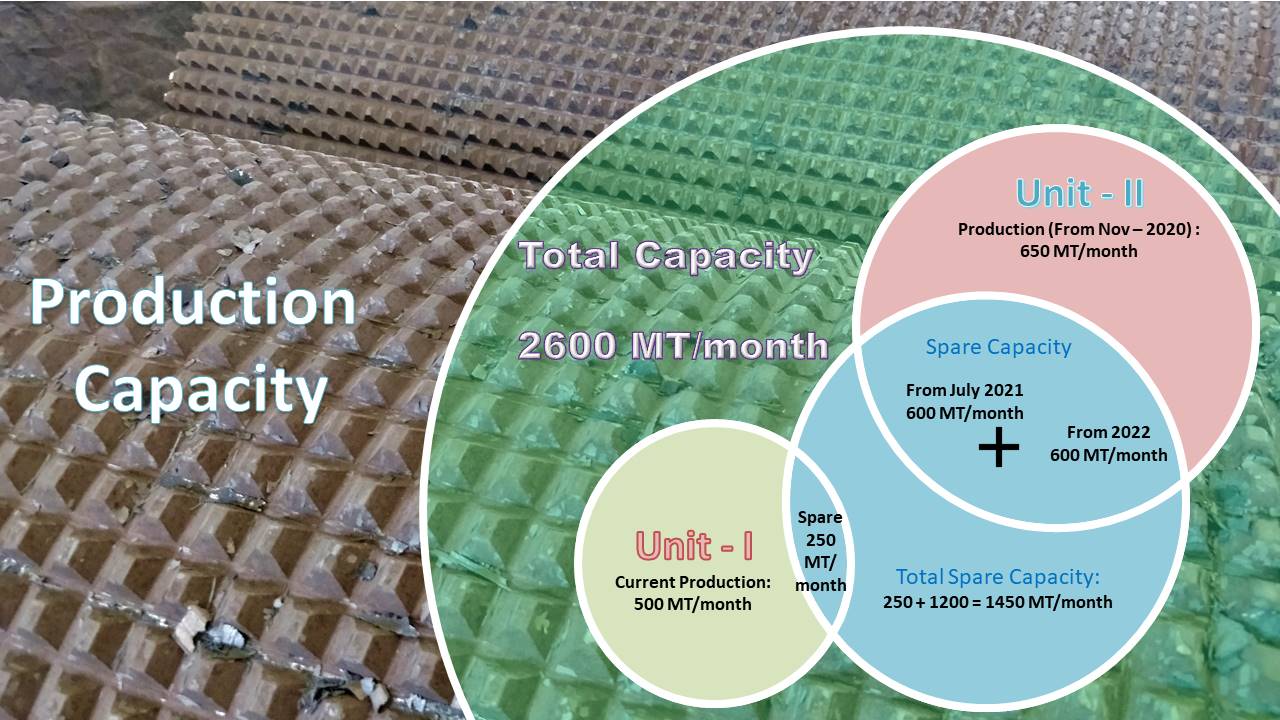

Infrastructure

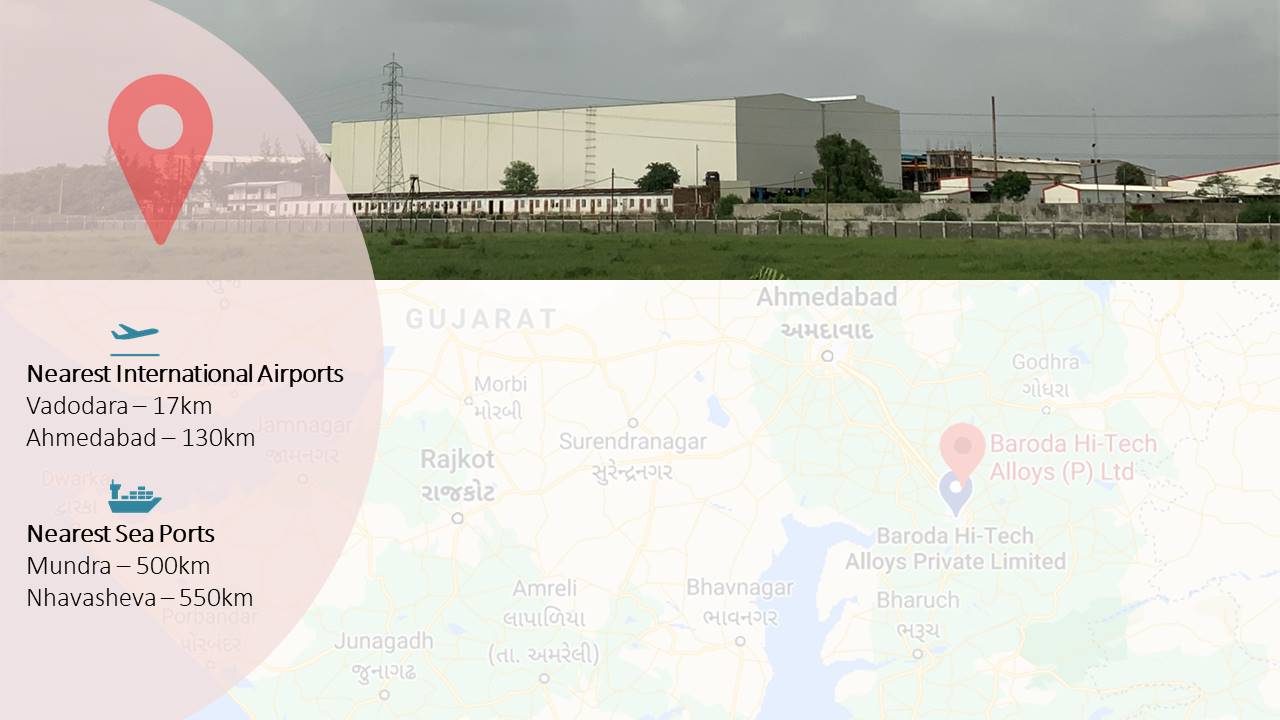

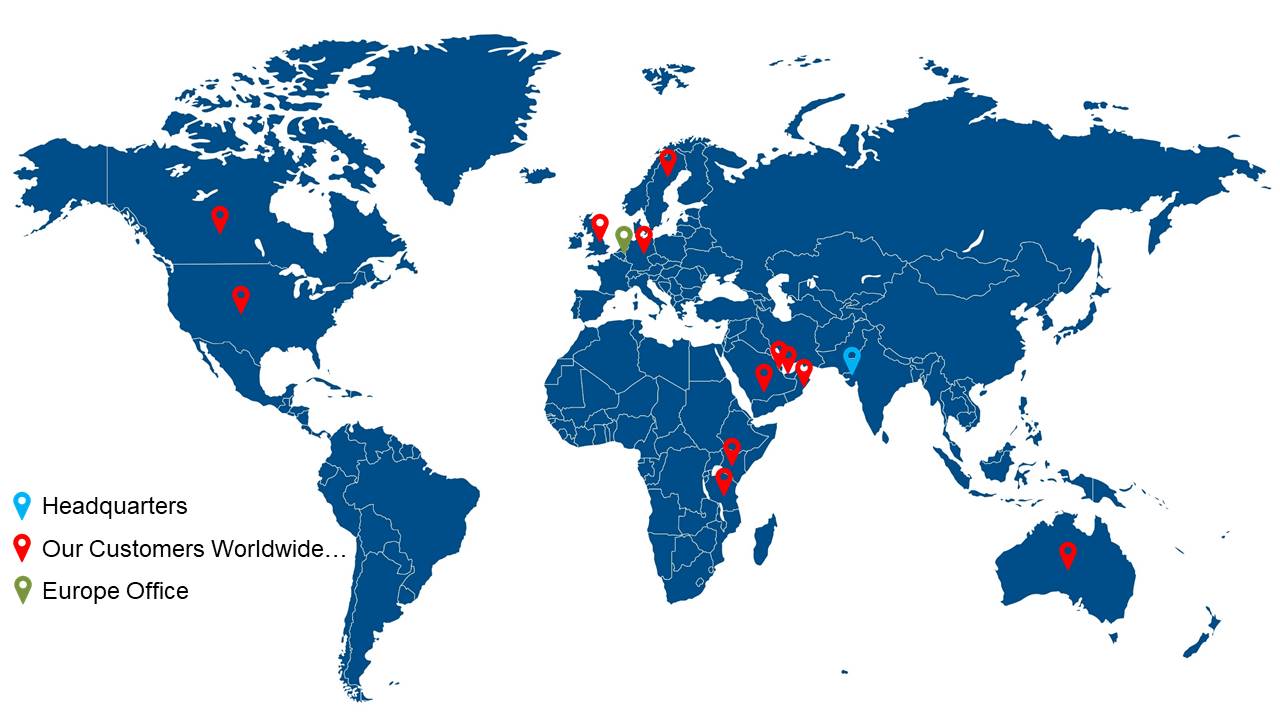

Baroda Hi-Tech has a state-of-the-art manufacturing facility at Vadodara. These facilities include ultra-modern machines and equipments that meet stringent international standards. The company is conscious about its responsibility towards environment. The manufacturing processes and machineries are environment friendly.

The products are manufactured based on client requirements. Right from raw material purchase to the finished products, client preferences and needs are factored on top priority.

- Swing Frame Grinders

- Flexible Shaft Grinder

- Shot Blasting Machine (Table size 1.5 M)

- 600 AMP. Rectifier Welding Machine

- Airscrew compressor 185 cfm ELGI Make

- Pneumatic Chipping Machine

- Pneumatic pencil grinder

- Vertical Boring Machine 100mm Spindle Dia

- Vertical Boring Machine 75mm Spindle Dia

- Vertical Boring Machine 1200mm Spindle Dia

- Milling Machine, Planner Machine, Shaping Machine, Radial Drilling

- Automatic resin sand mixer with PLC control (For Two partfinotech molding process)

- Vibrating Table 3.5 Meter x 2.5 Meter

- SandMuller500Kg.

- Sand Mixture 250 Kg.

- Different Sizes Molding Boxes

- Pneumatic Ramming Machine

- Mould Hardness Tester

Induction Furnaces

- 350 KW medium Frequency Induction Furnace, Make: M/s Power Cone Engineers, Ahmedabad - 500 Kg & 1000 Kg Crucible

- 750 KW medium Frequency Induction Furnace, Make: M/s Inductotherm (India) Pvt Limited, Ahmedabad - 2000 Kg & 2500 Kg Crucible

- 3500 KW medium frequency induction furnace, Make: M/s Power Cone Engineers, Ahmedabad - 10000 Kg Crucible

Pouring Laddles

- Bottom Pouring Laddie 15 MT

- Bottom Pouring Laddie 10 MT

- Bottom Pouring Laddie 5 MT

- Tilting Pouring Laddie 2 MT

- Tilting Pouring Laddie 500 Kg

- Tilting Pouring Laddie 300 Kg

Solution Annealing - Furnace number 1

- Heat Treatment Furnace 5 MT batch capacity ceramic wool lining with four oil fired burners and recuperate exhaust system

- 3 Point Temperature recorder with temperature & control system

- 5 MT Fork Lift Crane which can lift the material from the furnace and quench in the water within 45 seconds

Solution Annealing - Furnace number 2

- Heat Treatment Furnace 15 MT batch capacity ceramic wool lining with four oil fired burners and recuperate exhaust system

- 6 Point Temperature recorder with temperature & control system

- 15 MT Fork Lift Crane which can lift the material from the furnace and quench in the water within 45 seconds

Quality

Baroda Hi-Tech has modern Quality Control facilities. This enables the company to manufacture various critical grades of alloy steel castings conforming to national and international standards.

The company produces castings through stringent quality checks at all stages.

- Stage I: Raw material inspection

- Stage II: In process inspection

This involves checking of chemical composition, hardness (as cast) and visual inspection.

- Stage III: Final inspection

This covers verification of chemical composition for all pouring heats, dimensional inspection, NDT (radiography / ultrasonic), mechanical properties, micro structure, pull test, drop test, weight tolerances, etc.